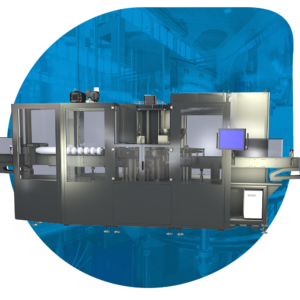

CSS121 and CSS242: INDUSTRIAL MACHINERY FOR MEDIUM PRODUCTION OF SOFT DRINKS IN CANS

Ecocap's CSS121 and CSS242 industrial packaging machines can be used in any medium-sized production plant of breweries and other beverage producers.

Ecocap’s, the unique and worldwide patented system to protect and give visibility to cans, is suitable for any type of can, thanks to its compatibility with any packaging solution, and exploits 100% customizable and recyclable caps. CSS121 and CSS242 are industrial machines for the packaging of “medium” sized cans, suitable for the production of soft drinks, beers, mineral waters, and other beverages. Both are equipped with rotary and flexible technology and can have different layouts.

the machine born for medium beverage producers

The CSS121 is a machine for the packaging of soft drinks, beers, and canned mineral waters developed for dynamic production lines. It produces up to 250 cans/minute and has a flexible layout. It is equipped with Hi-tech Concept with servo motor control and a user-friendly operator console. Ecocap’s provides a complete solution with on-site and remote training, scheduled maintenance, and the supply of Topsyl aluminum can covers can take place directly by Ecocap’s.

CHARACTERISTICS OF THE CSS121 PACKAGING MACHINE

DIMENSIONS OF THE CSS121 PACKAGING MACHINE

the ideal machine for medium production of cans

The CSS242 is a canned soft drink packaging machine developed for dynamic production lines: it produces up to 420 cans/minute and has a flexible layout, with Hi-tech Concept with servo motor control and a user-friendly operator console. It is equipped with 2 warehouses for the aluminum lids, therefore it can work simultaneously with Topsyl of two different designs. Ecocap’s provides a complete solution with on-site and remote training, scheduled maintenance and the supply of Topsyl takes place directly by Ecocap’s.

CHARACTERISTICS OF THE CSS242 PACKAGING MACHINE

DIMENSIONS OF THE CSS242 PACKAGING MACHINE

SEALING MACHINES RANGE